Soil purification Wet Mechanical Processing - Technology That Adds Value

The wet mechanical processing plant (soil washing plant) at the Eichenberg disposal center accomplishes the cleaning of contaminated soils/excavation material – leading to the production of high-quality secondary raw materials that can be reused.

The pollutants present in the soil are separated from the soil particles through a multi-stage process and enriched in the filter cake based on their physical properties. This concentrated mass of pollutants, consisting of fine particles and adhering pollutants, is separated during the washing process, allowing the cleaned aggregate to be discharged. The soil "washed" in this way and the aggregates and gravels produced from it become usable as high-quality recycled products. Overall, up to 80% of the previously contaminated input material can be reused.

Contact persons

Production of quality-controlled recycled construction materials

With approximately 200 million tons, mineral waste represents the largest waste stream in the Federal Republic of Germany (Source: Federal Association of Recycling Construction Materials e. V.). This enormous amount of material consists, among other things, of construction and demolition waste such as concrete, building rubble, and soil, which also arises during the renovation of the transportation network.

To manage these masses ecologically and economically sustainably, Max Wild offers a diverse recycling competence center at the Eichenberg site, which generates recyclable secondary raw materials from mineral waste using state-of-the-art processing technologies.

Secondary Raw Materials: Working for Construction and the Environment

Since the acceptance of using secondary raw materials is often lacking nowadays, the production of tested, quality-controlled, and certified recycled construction materials is particularly important. And this is exactly what Max Wild provides at the Eichenberg disposal center: all secondary construction materials recycled there meet the high quality standards for civil engineering and road construction, such as frost protection or sub-base material.

Through this quality promise, companies can refrain from using primary raw materials for these construction areas, which not only adds to the positive sustainability factor but also brings direct financial benefits.

Certified Material for Reuse

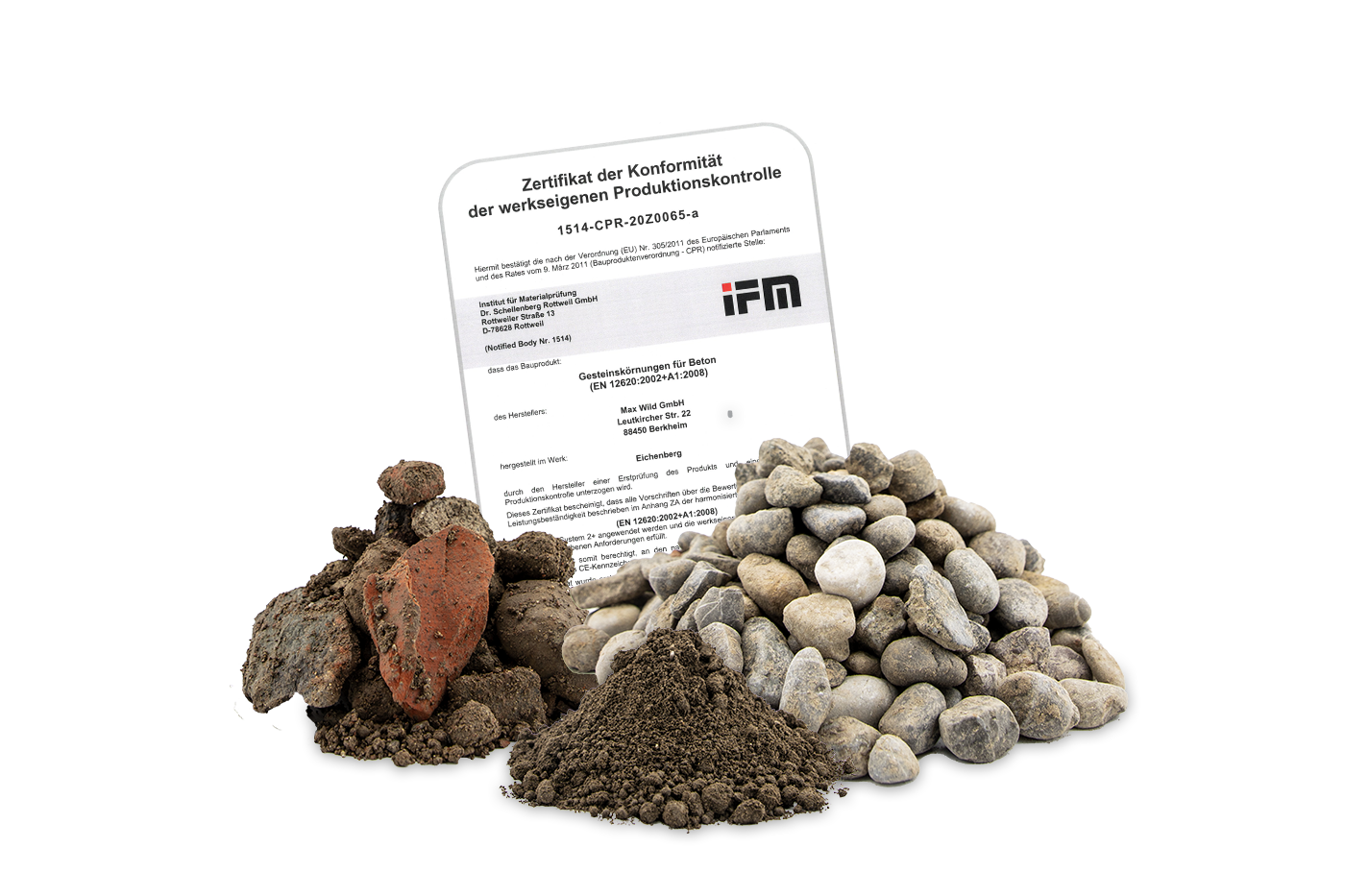

Soil after our wet mechanical processing: CE certified products

- CE marking through external monitoring

- Products can also be used as aggregates in asphalt and concrete mixing plants

Possible uses of soil and construction rubble after wet mechanical processing

- Concrete blocks

- Floor plates

- Precast concrete elements

- Basement walls

- Floor slabs

- Asphalt aggregates